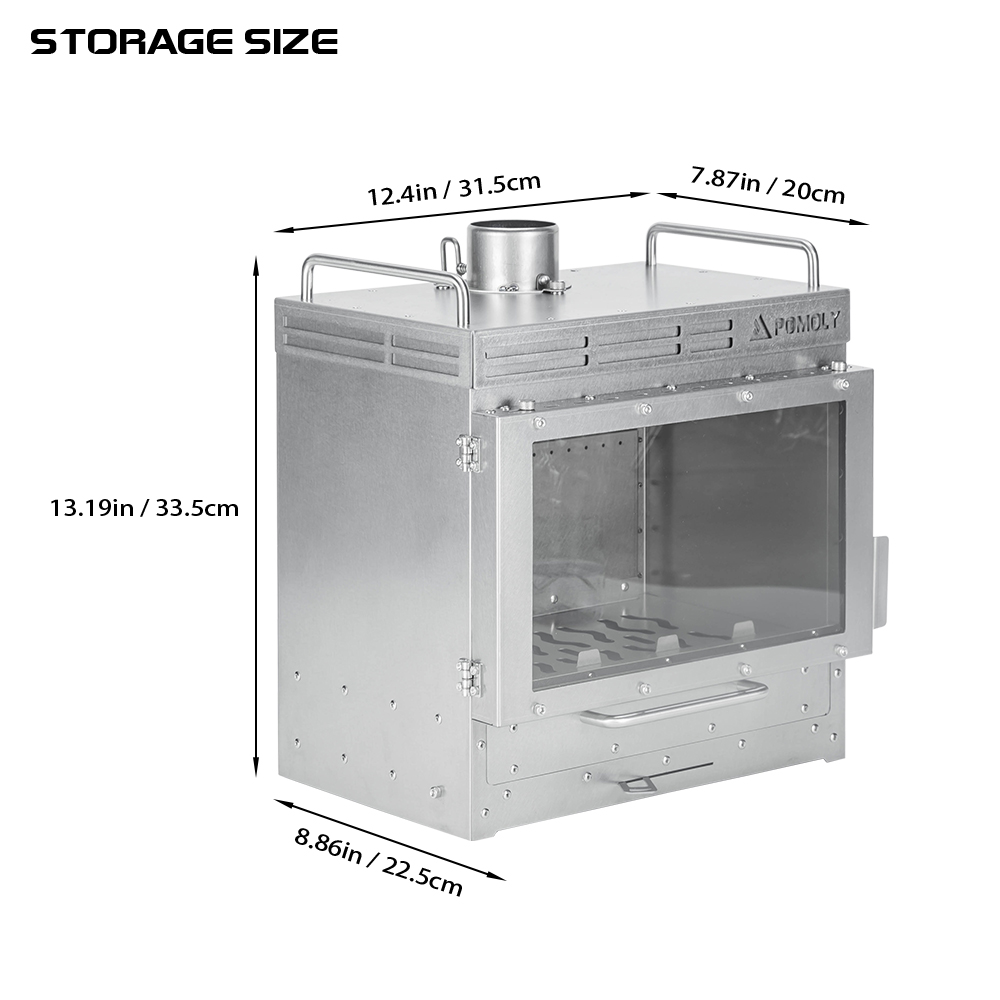

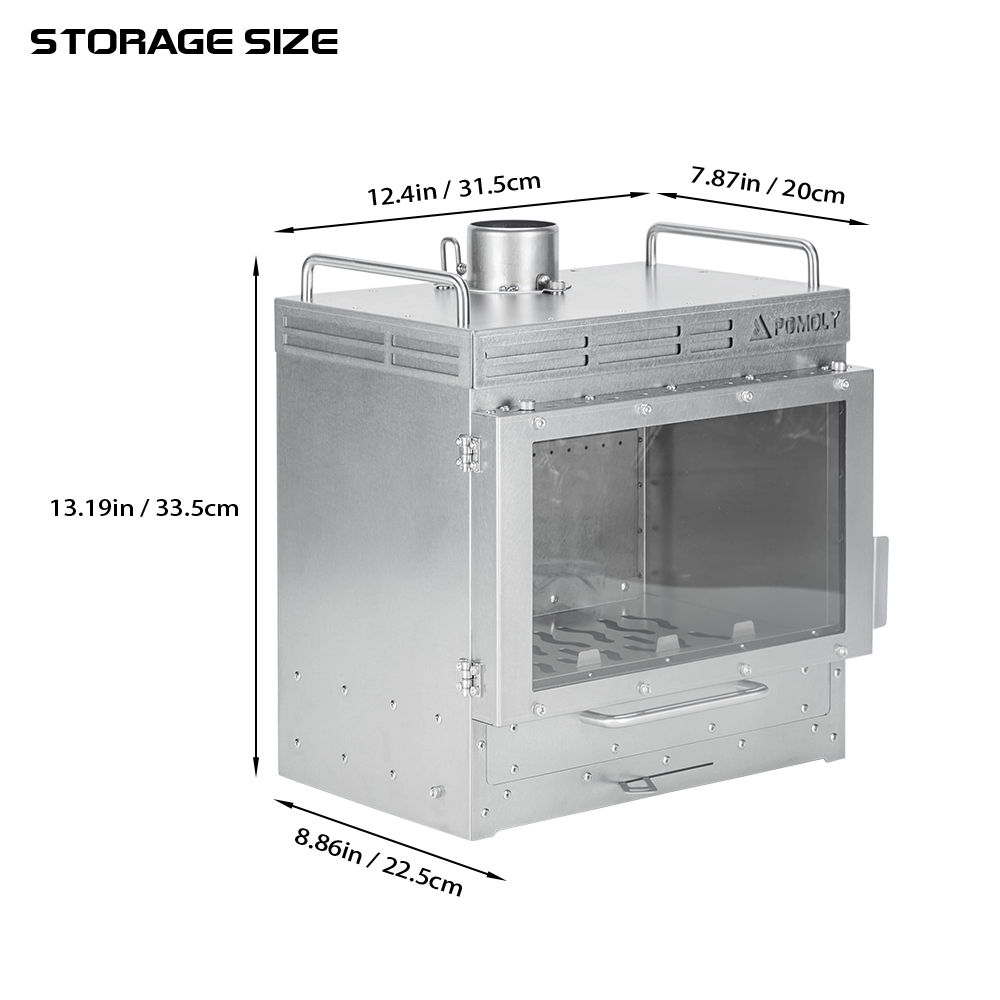

Dweller-Ti Titanium Wood Stove | Segmented Titanium Chimney Version | Zpoint & GREEN STOVE New Arrival

-

Detail

Zpoint & GREEN STOVE Dweller-Ti Wood Stove

Segmented Chimney Version

Dweller-Ti combines the original design of GREEN STOVE and the best processing technology of Zpoint to reduce the original weight from 22.7lb(11.8kg) to 9.5lb(4.3kg). The firebox is made of 0.6mm pure titanium, The top and support legs of the stove are made of 1.0mm pure titanium, which not only gives consideration to portability but also ensures the durability of the whole stove.

Dweller-Ti has all the functions and original design of Dweller. It can be compatible with titanium roll-up chimney and titanium integrated chimney at the same time. Zpoint classic adjustable chimney damper is also used on the dweller-Ti to control the exhaust system and burning rate of the stove. In addition, the sealing performance of dweller-Ti has been further improved.

WHAT'S INCLUDED:

Dweller-Ti Stove

10 Sections Titanium Chimney

Titanium Smoke Damper

Chimney Fixed Ring

YKK-Zipper Stove Bag

New Titanium Segmented Chimney

Three detachable rings for wind ropes fixing.

Reduce the hollow area, the convex is good for catching sparks.

Detachable Titanium Smoke Damper

Independent adjustable chimney damper facilitates accurate control of stove burning rate.

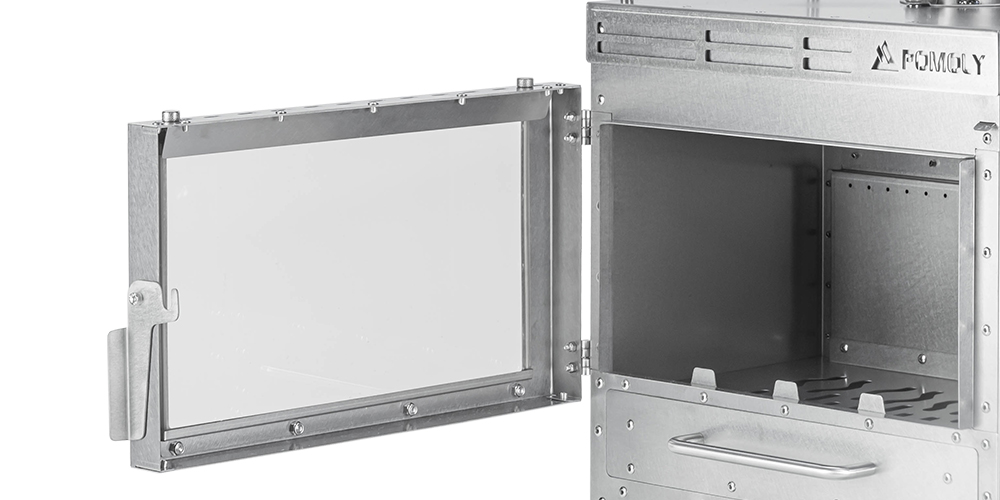

Larger Refractory Glass

Using a 11.4-inch refractory glass can not only enhance the atmosphere, but also observe the burning situation.

Unlike other Zpoint stoves, the direct visual experience brought by the flame through the huge glass is extremely attractive.

Precision Machining

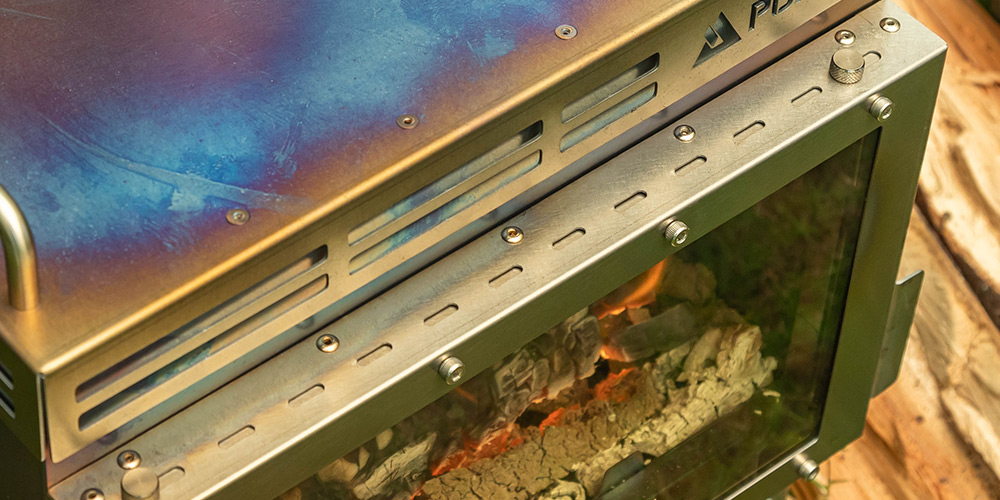

The Dweller-Ti stove is made of more sophisticated mechanical equipment to ensure that the gap between each part is reduced as much as possible, to prevent smoke leakage, and to make the stove body stronger.

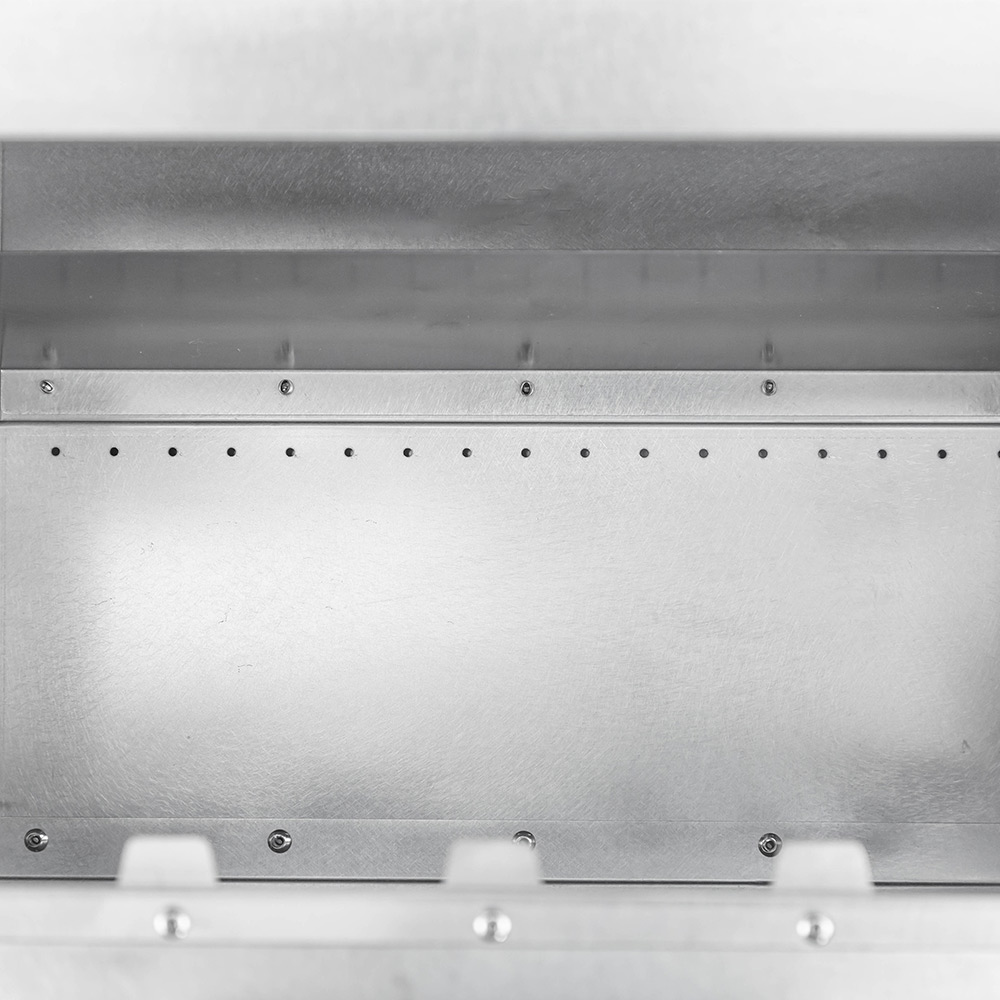

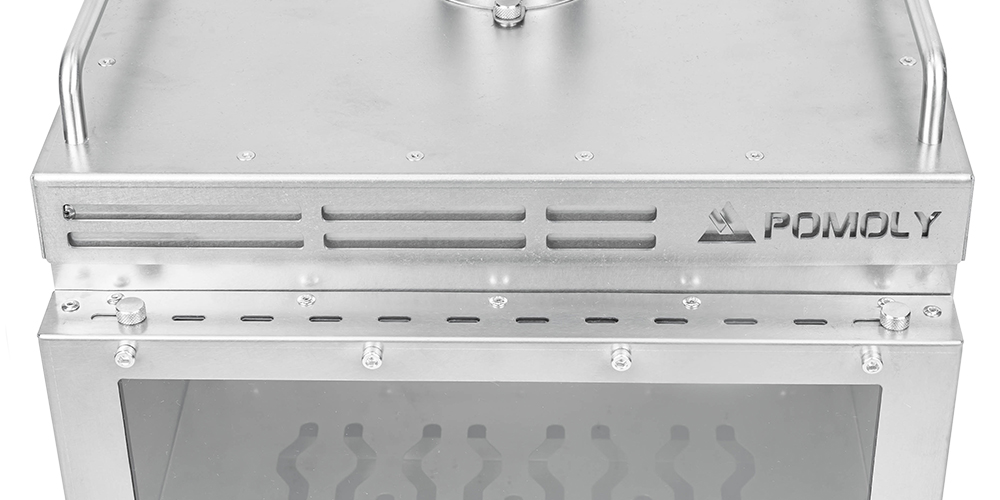

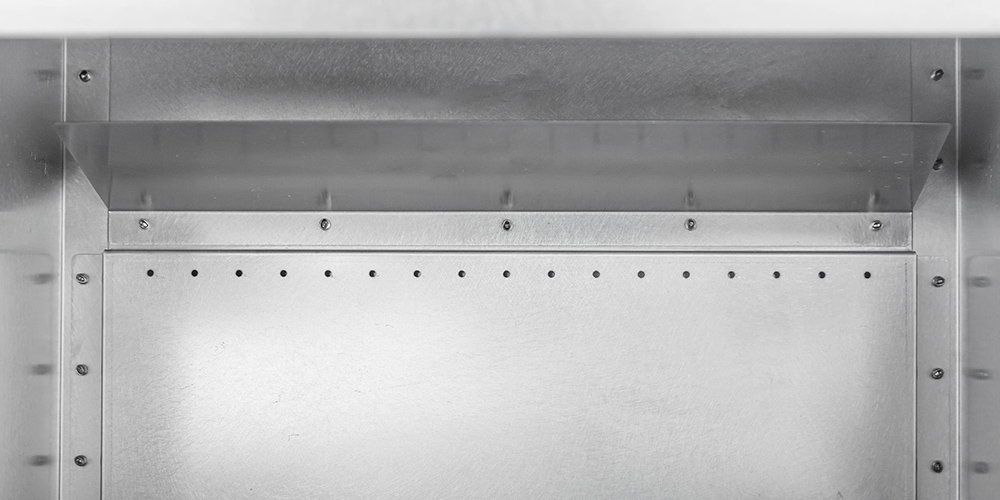

Air Curtain Technology

The purpose of the air curtain is to create a "secondary burn chamber." The particles of smoke rising on the hot gasses of the fire are trapped under the air curtain. These smoke embers and particles are then reburned. Then they can now escape through the chimney and appear more like waves of heat than smoke, The result is a very clean burn.The air entering from the top will move downwards, forming an "air wall" between the glass and the flame, achieving the effect of cleaning the glass and preventing the glass from turning black.The air curtain is closed before burning, once the fire has reached suitable strength, usually in 3 to 5 minutes, the air curtain can be open. The air curtain then runs at a steady state throughout the burn operation.

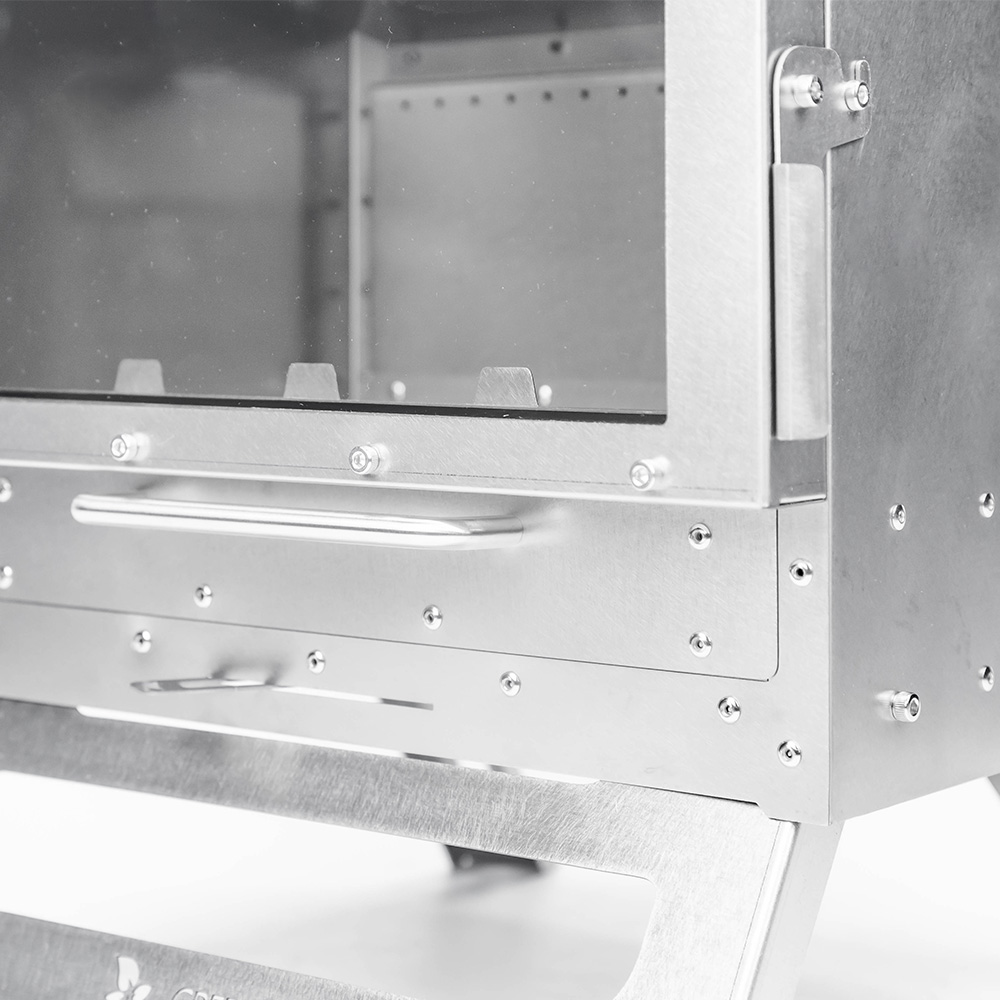

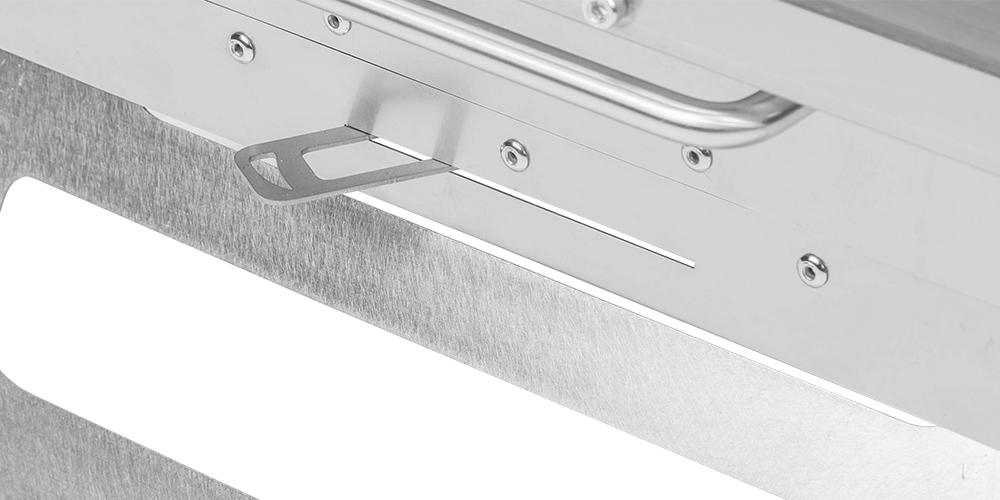

Bottom Air Intake and Slide Control

We changed our usual design and adopted the bottom air intake method. This design allows each firewood in the firebox to be fully burned. Compared with the horizontal air intake, this design is simpler and more effective.

The gap between stove parts is properly controlled. The switch at the bottom can provide maximum firepower when sliding to the left, and the air intake can be completely cut off to the right.

Secondary Air Intake and Baffle

The baffle can maximize the burning heat efficiency of the wood.The air enters the stove through the back air intake panel, which can allow the smoke generated by the burning wood to be reburnt, the heat can be concentrated inside the stove to increase the temperature of the stove. At the same time, there will be less smoke from burning wood.

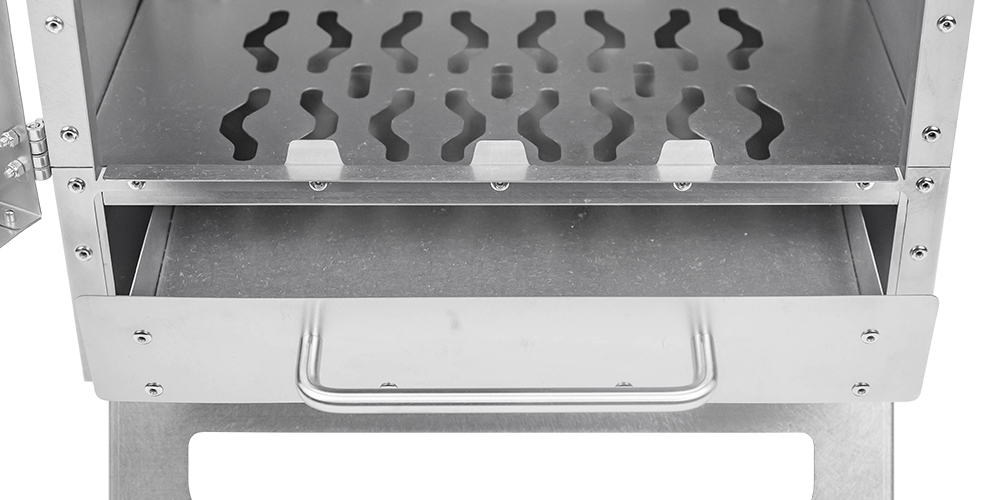

Drawer Type Ash Collecting Box

YKK-Zipper Stove Bag